Welcome to Ceramic Review

Ceramic Review is the magazine for contemporary and historical ceramics, ceramic art and pottery.

Ceramic Review Issue 326

March/April 2024

Ceramic Review is the magazine for contemporary and historical ceramics, ceramic art and pottery.

March/April 2024

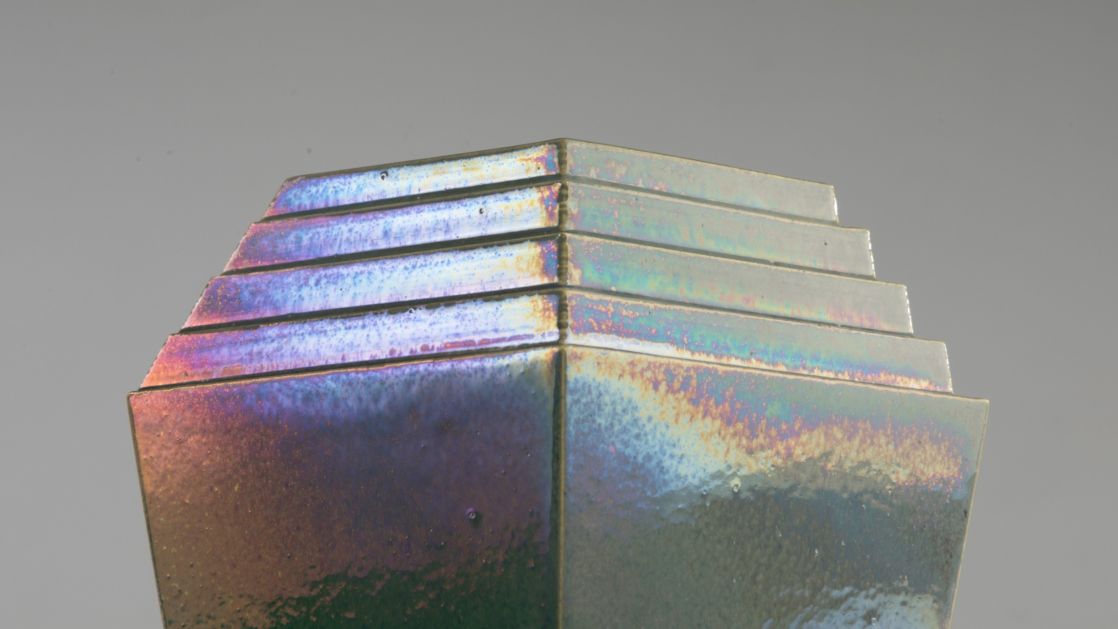

Alison Thyra Grubb worked extensively with in-glaze lustres during her studies to create geometric forms with rich iridescent surfaces. She shares how her interest began along with the recipes for creating them

Work by Alison Thrya Grubb; courtesy of the artist

I have been experimenting with in-glaze lustres for the past two years while completing my degree in Ceramics at Gray’s School of Art. I use 3D printing to create precise, geometric forms for slip casting and finish them with iridescent lustre glazes. These geometric vessels are inspired by the metal bismuth, which is an ingredient in many lustre glazes. I like the contrast between the unpredictable nature of lustre glazes on the predictable printed forms. I try to test new recipes in each firing and hope to one day develop a whole rainbow of lustre glazes.

My interest in lustre began when I visited the open studio of Fiona Duckett at Watergaw Ceramics in Scotland. Fiona has over 20 years’ experience with in-glaze lustre and she kindly shared her base glaze recipe with me, which I still use today. Throughout my degree I’ve been testing various additions of oxides in Fiona’s base glaze recipe and learning to refine the lustre-firing process.

I make my forms using white earthenware casting clay and bisque-fire them to 1180°C. After this, I apply glazes by either dipping or spraying, using a slightly thick application. I then fire the glazed pots in an electric kiln to 1020°C. Next, the glazes are fired for a second time in a gas kiln to cone 017. When the kiln reaches temperature, I close the flue leaving a 1-2 inch gap and reduce for 20 minutes. It is during this firing that a chemical reaction takes place and the metal oxides within the glazes will transform into metallic, iridescent lustres.

A single glaze result can appear different in each firing and one glaze may look different depending on which shelf it was on or how close it was to the flame. Lustre glazes can be quite unpredictable so I take notes during every firing to learn from my mistakes and recreate successful results.

BASE GLAZE RECIPE

Calcium borate frit 60g

Nepheline syenite 10g

China clay 10g

Ball clay 10g

Magnesium sulphate 3g

Work by Alison Thrya Grubb; courtesy of the artist

Work by Alison Thrya Grubb; courtesy of the artist

COLOUR VARIATIONS

Light blue (blue, purple and gold iridescence)

Silver nitrate 1g

Cobalt carbonate 1g

Green (gold, pink and blue iridescence)

Silver nitrate 1g

Cobalt oxide 1.5g

Gold (pink, purple and yellow iridescence)

Silver nitrate 1g

Bismuth trioxide 0.25g

Deep green/gold/blue (vibrant multi-colour iridescence when applied thickly)

Silver nitrate 1g

Cobalt oxide 1.5g

Bismuth trioxide 1.5g

Subscribe to continue reading this article in issue Ceramic Review Issue 301 (January/February 2020).

For more information visit alisonthyra.co.uk